Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

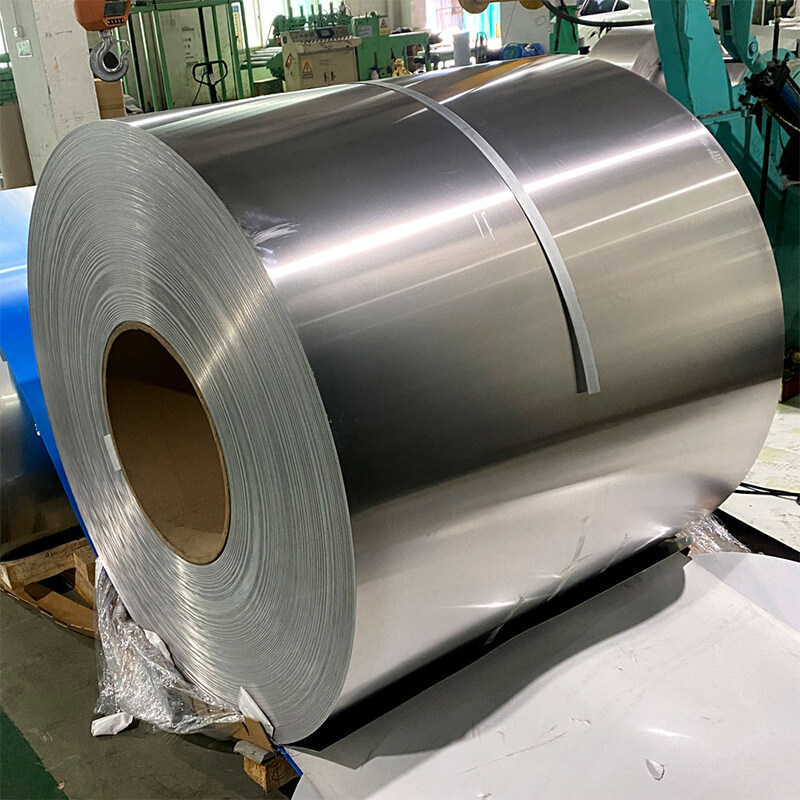

Coil 3003 6063 Aluminum Alloy sheet plate

Our 3003 and 6063 aluminum alloy sheets and plates are available at a low price, without sacrificing quality. You can choose the coil that best suits your needs, knowing that our products are designed to last for many years. Our aluminum coils are known for their exceptional performance, maintaining their smoothness and integrity even in harsh environments.

Have you found the low price coil of 3003 5052 6061 6063Aluminum Alloy sheet or aluminum plate? Here, you have come the right place. Any interests, welcome to contact us.

The Low Price Coil 3003 6063 Aluminum Alloy Sheet without sacrificing quality supports large stock. You can choose the coil that best suits your needs, knowing that our coils and sheets are designed to last for many years. They are known for exceptional performance, maintaining the smoothness and integrity even in harsh environments.

Good Heat Dissipation:

6063 aluminum alloy sheet is great at dissipating heat, which makes it perfect for use in heat sinks and other applications where managing heat is crucial. This means that it can effectively transfer heat away from sensitive components, helping to prevent damage and prolonging the lifespan of the equipment.

Lightweight:

The 3003 and 6063 aluminum alloy sheet is a lightweight material, which makes it a go-to choice for applications where weight is a major concern. This is especially true in industries like aerospace and automotive, where reducing weight can improve fuel efficiency and overall performance. Its lightweight nature also makes it easier to handle and transport, which can save time and money during the manufacturing process.

Excellent Anodizing Properties:

3003 6063 aluminum alloy sheet is great for anodizing, which means it can be easily colored or textured to create a decorative finish. This makes it a popular choice for use in applications where aesthetics are important, such as in architectural design or consumer products. Anodizing is a process that creates a protective layer on the surface of the aluminum, which can also improve its resistance to corrosion and wear.

Customized Luster:

6063 aluminum alloy sheet is highly customizable, which means that it can be tailored to meet your specific needs and preferences. Whether you’re looking for a matte or glossy finish, or a specific color or texture, we offer a range of customization services to help you achieve your desired look. So if you encounter any issues or challenges, don’t hesitate to reach out to us.

Product Parameter:

|

Material |

Aluminum Alloy Metal |

|

Technique |

Cold Rolled/ Hot Rolled |

|

Surface |

Mill |

|

Standard |

ASTM/ AISI/ JIS/ DIN/ GB |

|

Temper |

O - H112 |

|

Grade |

1000,2000,3000,4000,5000,6000,7000 Series |

|

Edge |

Mill Edge / Slit Edge |

|

Shape |

Sheet/ Coil |

|

Length |

Customized |

|

Thickness |

Customized |

|

Certification |

API, BIS, SABS, JIS, GS, ISO9001 |

|

Width |

10-1500mm or As Request |

|

Tolerance |

±3% |

|

Processing Service |

Bending, Welding, Decoiling, Punching, Cutting |

|

Application |

Aviation, Automotive, Packaging, and Other Industries |

Application of aluminum sheets

Aviation industry

The use of aluminum is greatly beneficial to the new aircraft and aerospace industry. Almost every aspect of modern aircraft uses aluminum sheets, including wing panels, hatches, fuselage, ball bearings, etc.

The aircraft needs to be as light as possible while maintaining the required structural strength, and aluminum, which accounts for 75-80% of the overall weight of the aircraft, is the best material to achieve this goal. In addition to improving fuel efficiency, aluminum also has strong corrosion resistance.

Automotive industry

The lightweight characteristics and cost performance of aluminum sheet ing make it suitable for lightweight vehicle construction. In the construction of engine hood and other structural elements, aluminum composite plates constructed from these plates are used.

Aluminum sheets' ability to reduce the weight of the front end of the vehicle allows higher acceleration, which can minimize fuel consumption and improve fuel economy.

Packaging industry

The simplicity of molded aluminum sheets brings great flexibility to the packaging industry - from fancy cans to distinctive packaging.

In addition, aluminum sheets are completely recyclable, which saves a lot of energy and has a very low carbon footprint. Its high corrosion resistance, antibacterial surface and non-toxic properties also make it suitable for packaging food and beverages, such as bottle caps, tubes, cans and drug packaging.

Other industries

Aluminum plates are also suitable for the manufacture of nameplates made of metal and other related products. With the use of aluminum, most car license plates are made of aluminum, which is very cheap because of its rich resources. Because of their corrosion resistance and very low maintenance, they are often used in this way.

You can also see aluminum plates used for packaging in the food and beverage industry, as well as aluminum plates as part of cookers and utensils. This kind of metal plate can also be used in roof, drainage ditch, side line and other forms in construction and housing industry.

The difference between 3003 aluminum plate and AA 5052 aluminum alloy

Aluminum alloy containing important element manganese exists in 3003 aluminum plate. Aluminum magnesium alloy AA / kloc-1 / aluminum alloy is mainly composed of magnesium. The aluminum content of aluminum 3003 plate is slightly higher than that of 5052 aluminum plate.

Size

Thick aluminum plates are mainly produced with alloy 3003, but thin aluminum plates and aluminum plates made of 5052 are also widely used.

Mechanical properties

The tensile strength of 3003h24 aluminum plate is 145-195rm/mpa, while that of 5052h24 aluminum plate is 230-280rm/mpa, which is much higher than that of 3003h24 aluminum plate.

The tensile strength of 3003h24 aluminum plate is 115rm/mpa, while that of 5052 H24 aluminum alloy is 150rm /MPa. Therefore, the performance of 5052 aluminum plate is significantly better than that of 3003 aluminum plate.

Scope of application

In the automotive industry, 3003 aluminum alloy is used to manufacture automotive battery housings, while 5052 aluminum sheet is used for plastic panels, windows, fuel lines and other similar applications. 3003aluminum has excellent pro characteristics, so it is often used in humid environment. Aluminum alloy AA 5052 is also used in electrical insulators, transportation vehicles, pressure tanks, oil pipelines and other applications.

Price

The current price of 3003 aluminum sheet is slightly higher than that of plain aluminum sheet, but 5052 aluminum sheet is much more expensive.

strength

In contrast, 5052 is stronger, and has excellent corrosion resistance, tensile property, machinability, high strength, and can also be welded, while 3003 is relatively soft, with good corrosion resistance, tensile property, machinability and medium strength, so it is solid and durable.